1. The Right Pressure

The tyre is the only point of contact between your vehicle and the road; it is essential both for the safety of users and for the security of the goods transported. Optimise your tyre pressure for improved safety, to save fuel and increase the service life of your tyres.

THE INFLUENCE OF TYRE PRESSURE ON SERVICE LIFE

When inflating the tire, do not crouch in front of the tire or the mounting surface of the rim.

Do not keep the inflating tires unattended. Use a safety cage when inflating and use an air compressor with a regulated pressure.

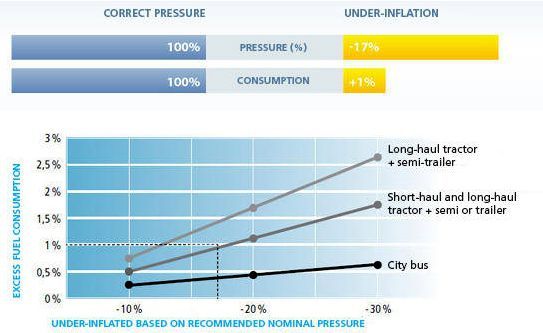

If the air pressure is higher than the specified standard of 20%, the tire life will be reduced by an average of 9%; If the air pressure is lower than the specified standard of 20%, the tire life will be reduced by an average of 17%; If the tire pressure is too high or too low (more than 50%), then the tire will be scrapped, and will lose use value.

I *% | 彳谱里程% | ns% | 行驶里程% 1 |

125 | 88 | 85 | 90 |

120 | 91 | 80 | 83 |

115 | 94 | 75 | 80 |

110 | 95 | 70 | 74 |

105 | 98 | 65 | 68 |

100 | 100 | 60 | 61 |

95 | 97 | 55 | 55 |

90 | 94 | 50 | 48 |

When the air pressure is not enough, it will easily incur two shoulders’ abnormal wear; it will easily cause early damage of the tread; it will easily cause slip phenomenon; ride will be deteriorated; it will waste fuel; and it will easily cause separation of cord because of heat.

When the air pressure is too high, the center tread will occur abnormal wear; when tires encounter obstacles, they are easy to blast; prone to beating and thus affect the ride comfort.

Recommended pressure keeps even contact between tread and road surface, and prolong tire’s life.

The air has the characteristic of expanding with heat and contracting with cold, so when driving at high speed, the pressure will increase, then the pressure need to be controlled and inspected correctly.

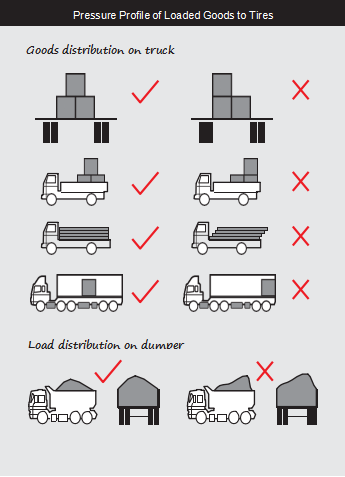

There is a corresponding relationship between load and pressure, so overload is equal to low pressure, and thus causing tire’s damage. Often using under overload situation, tire’s using life will decrease 20% to 50%. Wrong load method will influence driving safety, and also cause uneven load of tire, making certain tire overload. Overload will shorten tire’s potential life and cause the tire cannot retread.

2. Tyre Inflation

Pneumatic pressure is the life of the tire, and also the safety of driving safety, so tire pressure must meet the national standard of the tire specified pressure for different types and specifications.

Tire pressure must be checked in the cooling state of the tire, and must not be adjusted under the hot tire pressure. Please use a good barometer to measure the air pressure, and calibrate regularly. High pressure and low pressure will all result in irregular, cracks at the bottom of the grooves, brakes of the cord, delamination of the carcass plies, tire blasting and other damage. When driving at high speed continuously, air pressure should be increased 5 ~ 10% of the standard air pressure. After the tire is running, the internal pressure rises as the temperature rises, during this period tires should not deflate. When driving, one should pay attention to the tire’s situation, once leak of the tire is found, one need to stop to inspect (if necessary, put on the spare tire), in order to prevent tire crushing due to serious flaws.

3. Maintenance

Find out about advice from YUELONG for the maintenance of your truck, bus and coach tyres to optimise safety and service life of the tyre.

3.1 Take Care of Your YUELONG Tyres

a) Carry out regular checks on your YUELONG tyres to look for uneven wear and / or any damage.

b) verify the wheel tightening torque using the recommendations made by the vehicle manufacturer or axle supplier.

c) Have a tyre professional conduct an in-depth (internal / external) examination of any damage found to the tread, sidewalls and bead area. This also applies to any damage to the rim.

It is dangerous to ignore a damaged tyre. YUELONG truck tyres can be repaired under certain conditions. However, not all kinds of damage can be repaired. Repairing a tyre is a job for trained and qualified professionals. The tyre repairer always has sole responsibility for the accuracy and quality of the work done on the tyre. Repair must always be preceded by removal of the tyre and a thorough inspection both internal and external, by the professional.

Do not put back in to service any tyres that show signs of damage such as: deformed or exposed bead wire; delamination between rubber and plies; internal corrosion; presence of marbling, creasing or abrasion of the interior lining and over flexing of the reinforcing structure owing to the deflated or severely under inflated running. At each vehicle inspection check the state of the valve. If in any doubt replace.

To maintain even wear of the tires, tire rotation of the vehicle is needed timely and appropriately. By rotation or reverse, the tire can avoid about 20% mileage wear. Tires whose outer diameter is largish should be installed on the outer wheel. Generally, radial tires that drive 12000km to 15000km should make a transposi- tion, and bias tires drive 8000km to 10000km should make a transposition. There are two kinds of tire rotation, that is, cross rotation method and cyclic rotation method. The cross rotation method is applied for vehicles usually driving on the large arched road surface; and the cyclic rotation method is applied for vehicles often driving on the flat road. Once a method is chosen, it should always be used in this way. Radial tires’ rotation direction should never change. Once rotated reversely, the steel cord will incur inverse deforma- tion and shake, and thus resulting in deterioration of vehicle’s smoothness.

When do the transposition, the cover tire, inner tire and protecting band should all be checked. Once any outer injure of the tire found, a timely reparation is needed. Tire maintenance should keep in pace with vehicle’s first and second level of maintenance.

The Relationship Between Load and Mileage

Load Rate % | Mileage% | Load Rate % | Mileage |

70 | 200 | 120 | 65 |

80 | 160 | 130 | 60 |

90 | 120 | 140 | 45 |

100 | 100 | 150 | 41 |

110 | 82 |

If the load is 20% higher than the specified standard, the tire life will be reduced by an average of 35%.

If the load is 50% higher than the specified standard, the tire life will be reduced by an average of 59%.

3.2 Product Life Time

Tyres consist of different types of rubber based materials and components whose properties are essential for the tyre itself to work properly. These properties change over time. Changes to the properties of a tyre depend on numerous factors such as the climate, the storage conditions for your tyres: temperature, humidity, position etc; the conditions when in use: load, speed, tyre pressure, damage sustained due to the condition of the roads etc.

That is why, in addition to regular inspections and inflation pressure maintenance by operators, YUELONG recommend that tyres, including spare tyres, should be inspected regularly by a qualified tyre specialist, who will assess the tyre’s suitability for continued service. Tyres which are in use for 5 years or more from their date of manufacture should continue to be inspected by a specialist at least annually.

Operators are strongly encouraged to be aware not only of their tyres’ visual condition and inflation pressure but also of any change in dynamic performance such as increased air loss, noise or vibration, which could be an indication that the tyres need to be removed from service. The date when a tyre was manufactured is located on the sidewall of each tyre. Operators should locate the code on the tyre which begins with the letters DOT and ends with the week and year of manufacture. For example a DOT code ending in “2204” indicates a tyre made in the 22nd week (May) of 2004.