Analysis of Tyre Problems ⅠTyre Crown

1. Delamination between Tread Rubber and Steel Belt

Symptoms: The delamination happens between the tread rubber and steel belt. The interface of it was smooth, sometimes accompanied by wear.

Causes: ① In tyre’s manufacturing, the adhesion of rubber was poor.

② Component materials have been left for too long or the surface was frosted.

③ Components were improperly positioned or not compacted tightly.

Liability attribution: Manufacturing issues

2. Steel Belt Delamination

Symptoms: The delamination happens among the layers of steel belt. The interface of them was smooth, sometimes accompanied by wear of wires.

Causes: ① In the process of tyre manufacturing, water and gasoline were left among the parts of the steel belt;

② In addition, there were bubbles, dust and other impurities.

Liability attribution: Manufacturing issues.

3. Delamination Between Carcass and Steel Belt

Symptoms: The delamination happens between the steel belt and carcass. The interface of it was smooth, sometimes accompanied by wear of wires.

Causes: ① In the process of tyre manufacturing, the water and gasoline were left among the parts of the steel belt.

② There were oil, dust and other impurities.

③ The tire pressure was insufficient or the pressure does not match the load.

④ Long-haul driving at high speed for a long time.

Liability attribution: Performance/Quality problems.

4. Crown Burst

Symptoms: The crown explodes and the steel belt was pulled out; Rubber properties of the crown were changed, which was severely accompanied by oil flow.

Causes: ① The steel belt near the crown were punctured and not repaired in time.

② The tyre pressure was relatively insufficient or pressure and load was not matched.

③ When the vehicle was running, the speed was too fast and the tyre temperature was too high, which causes the rubber aging among the parts.

Liability attribution: Performance/Usage problems.

5. Crown Burst

Symptoms: The crown explodes and the belt was pulled out, sometimes accompanied by wear of wires.

Causes: ① In the process of tyre manufacturing, the water and gasoline were left among the parts of the steel belt.

② There were oil, dust and other impurities.

③ The joint of zero-degree cap ply was impacted and broken.

④ The tyre pressure was relatively insufficient or pressure and load was not matched.

Liability attribution: Manufacturing/ Performance/Usage problems.

6. The Joint of Zero-degree Cap Ply was Broken

Symptoms: The joint of zero-degree cap ply was broken.

Causes: ① In the process of tyre manufacturing, the water and gasoline were left on the joint of cap ply.

② There were oil, dust and other impurities.

③ The joint of zero-degree cap ply was too small or not compacted tightly.

④ If the tyre pressure was too high or the load was too large, the instantaneous impact of the zero-degree cap ply will be forceful when it encounters the road buffer or the curb, causing breakage.

Liability attribution: Performance/Usage problems.

7. Crown Blasting

Symptoms: The crown was blasted and the steel belt wire was broken. There was obvious trauma on the tread rubber.

Causes: ① The crown was cut by sharp objects such as stones and iron in the driving, and the belt was broken, causing blasting.

② The crown of the tyre was blown up by the impact of obstacles driving through the ditch.

Liability attribution: Usage problems.

8. Insufficient Vulcanization

Symptoms: The tread rubber looks like honeycomb on the surface or inside at the crown.

Causes: The vulcanization of tyres was insufficient.

Liability attribution: Manufacturing issues.

9. Tread Rubber Cracking

Symptoms: The rubber joint of the tread was cracked, and the surface of the crack was smooth and has a certain slope.

Causes: ① During the manufacturing process, the surface of the tread rubber joint was contaminated with water, oil, dust, etc.

② Inadequate adhesion of tread rubber joint.

Liability attribution: Quality problems.

10. Crown Blasting

Symptoms: ① The crown was impacted by external force, and the steel belt wires were broken and torn, without delamination between components.

② There was no obvious trauma on the broken tread rubber.

Causes: ① The tyre hits obstacles, running at high pressure, high load or high speed.

② The vehicle forcibly pass through the ditch and suffers instant impact.

Liability attribution: Usage problems.

11. Cutting Blasting

Symptoms: ① The crown was impacted by the cutting of the outer objects, and the wires of the steel belt were broken and torn, without delamination between components.

② There was no obvious trauma on the broken crown.

Causes: ① The tyre hits obstacles, running at high pressure, high load or high speed.

② The driver has bad driving habits.

Liability attribution: Usage problems.

12. Block Dropping of the Crown

Symptoms: ① The crown was pierced by external objects and the blocks were torn. There was no delamination among the parts.

② There was no obvious trauma on the broken crown.

Causes: ① The rigidity of the crown was increased because the air pressure was too high, and the tyre was stabbed or bitten by gravel or obstacles, causing local drops.

② The crown was bitten off by stones due to bad driving habits, emergent braking or acceleration.

Liability attribution: Usage problems.

13. Crown Piercing

Symptoms: ① There were obvious puncture on the crown.

② The inside part of the tyre corresponding to the fault was penetrated.

Causes: The crown was pierced by sharp objects such as nails and iron blocks, and penetrates the steel belt and carcass wires in driving.

Liability attribution: Usage problems.

14. Block Dropping of the Crown

Symptoms: The tread rubber has the phenomenon of dropping blocks and the wires of steel belt were exposed in severe cases.

Causes: ① It was caused by excessive acceleration or sudden braking when the tire was driving on gravel or non-paved roads.

② Poor road conditions or bad driving habits of drivers.

Liability attribution: Usage problems.

15. Puncture to the Crown Causes Bulging

Symptoms: The tread rubber was punctured and the wires of steel belt were broken, causing bulging in the opposite driving direction.

Causes: The steel belt was pierced by sharp objects in driving. Due to the erosion of air or water, there was delamination among parts. In addition,the tyre runs into air, causing shoulder bulging in the opposite driving direction.

Liability attribution: Usage problems.

16. High Pressure Wear

Symptoms: The middle part wears out too fast around the crown.

Causes: ① Tyre pressure was relatively high.

② The vehicle was overloading.

Liability attribution: Usage problems.

17. Low Pressure Wear

Symptoms: Compared with the pattern in the middle of the tire, the pattern on both sides wears out too quickly.

Causes: ① Insufficient pressure.

② Air pressure and load do not match.

③ Vehicle was in bad conditions.

Liability attribution: Usage problems.

18. Crown Puncture and Blasting

Symptoms: The crown burst and the tread rubber fell off. The steel belt was loose and accompanied by rust.

Causes: ① The crown was pierced and not repaired in time in driving. Due to the penetration of air or water, the wires of steel belt were corroded and the strength was reduced. The delamination among the components was caused. The tread rubber was thrown off if continue to drive.

② Bad driving habits, not paying attention to maintenance.

Liability attribution: Usage problems.

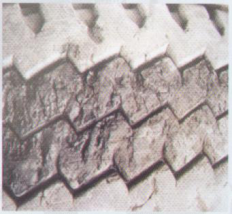

19. Fish Scale Wear

Symptoms:The edges of the tread pattern of the tyre look like fish scales due to wear.

Causes: ① The tyre was used in the environment where the vehicle was frequently stopped, driven with high torque and frequently braked.

② Inadequate tire pressure.

③ The wear can occur if the double tyres were not properly installed and the strength of the suspension spring or shock absorber was not uniform.

Liability attribution: Usage problems.

20. Block Dropping of the Crown

Symptoms: The tread rubber was dropping blocks and torn.

Causes: ① The pressure was too high, and the rigidity of the crown was enhanced. The gravel can easily bite the tread rubber and cause the block to fall in driving.

② Drivers have bad driving habits. Acceleration or irregular brakes can easily cause tread rubber biting.

Liability attribution: Usage problems.

21. Crown Partial Wear

Symptoms: The tread rubber was partially worn soon.

Causes: ① The brake was locked with heavy load trailer due to the vehicle's emergent brake or poor braking system.

② Unbalanced air pressure of the double tyres in the rear axle.

Liability attribution: Usage problems.

22. Crown Partial Wear-out

Symptoms: The partial tread rubber was worn severely, evenly or thoroughly.

Causes: ① The brake was locked with heavy load trailer due to the vehicle's emergent brake or poor braking system.

② Unbalanced air pressure of the double tyres in the rear axle.

③ The tread rubber was partially corroded and continues to be used.

Liability attribution: Usage problems.

23. Partial Peeling of Tread Rubber

Symptoms: The modification of tread rubber loses its original physical and mechanical properties.

Causes: When the surface of the tyre was eroded by oil, electrolyte, strong acid, strong alkali or organic solvent,

the partially modified rubber will fall off while driving.

Liability attribution: Usage problems.

24. Partial Peeling of Tread Rubber

Symptoms: ① The modification of tread rubber loses its original physical and mechanical properties.

② The tread rubber has been worn off partially.

Causes:After the tyre surface was eroded by engine oil, electrolyte, strong acid, strong alkali or organic solvent, the tread rubber will peel or bulge, and the modified rubber will fall off due to wear during driving.

Liability attribution: Usage problems.